How Timely Industrial Electrical Repairs Prevent Costly Downtime for Businesses

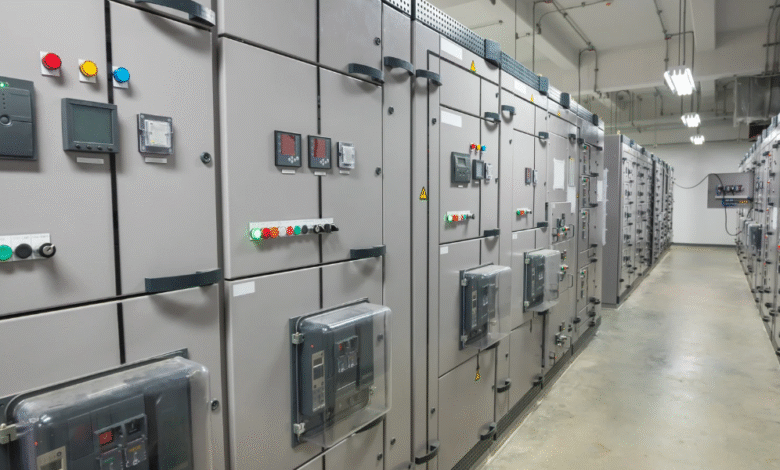

In high-demand industrial settings, even a brief disruption in electrical systems can halt operations, impact revenue, and damage sensitive equipment. Businesses that rely on complex power systems cannot afford to wait for failure before taking action. Securing industrial electrical repairs in Oklahoma City early on ensures the infrastructure remains stable, operations stay efficient, and unexpected breakdowns are minimized. Electrical malfunctions can be silent at first, but their consequences are far-reaching. From data loss to compromised safety, the ripple effects can quickly add up. Proactive electrical repair strategies help organizations prevent cascading failures and minimize long-term production losses.

Why Downtime Is So Expensive in Industrial Environments

A short pause in production is not just inconvenient; it translates to significant financial losses. Every minute of downtime costs labor hours, delays output, and impacts supply chain commitments. In facilities running 24/7, time truly is money. Electrical systems are the backbone of automation, HVAC, lighting, and security. Failing to address warning signs, such as power surges, circuit overloads, or equipment overheating, can disrupt multiple processes simultaneously. Prioritizing inspection and repair helps businesses stay ahead of avoidable shutdowns.

See also: 5 Services You Can Hire For Home Improvement

Signs Repairs Should Not Be Delayed

Many facilities experience early signs of electrical instability but fail to act until systems break down. Flickering lights, tripped breakers, overheating panels, and abnormal voltage fluctuations are all red flags. Waiting too long to act increases the risk of full system failure. Understanding the risks of delaying industrial electrical repairs helps identify why these issues demand immediate attention. What may start as a minor inconvenience could quickly escalate into hazardous conditions or irreversible damage to equipment.

The Role of Preventive Repair in Safety and Compliance

Timely repair work plays a significant role in regulatory compliance. Industrial sites must meet strict safety standards to protect workers and avoid violations. Damaged wiring, exposed connections, or overloaded panels are common OSHA concerns that trigger fines or shutdown orders. Preventive repairs also reduce liability exposure. Malfunctioning electrical systems are a known cause of fires, arc flashes, and equipment failures. A well-maintained system demonstrates due diligence and reduces insurance risks.

How Repairs Preserve Equipment Lifespan and Efficiency

Electric motors, conveyors, data servers, and automated systems rely on clean and stable power. Faulty wiring or voltage irregularities can shorten the lifespan of expensive equipment. Inconsistent performance also raises energy consumption and degrades productivity. Addressing faults early supports better system efficiency and preserves your investment in technology. Whether through load balancing, rewiring, or panel upgrades, timely repairs create a more resilient and optimized operation.

Selecting the Right Electrical Partner

Repairs are only as effective as the professionals executing them. That’s why choosing the right professionals for industrial electrical repairs is critical to long-term reliability. Certified technicians with industrial experience can assess the whole electrical infrastructure and implement lasting solutions. Look for partners who provide detailed diagnostics, documentation, and 24/7 service availability. Having access to experts who understand the complexities of industrial systems ensures fast resolution and fewer repeat issues.

Conclusion

Industrial electrical failures are not just technical problems; they are direct threats to productivity, safety, and profitability. Businesses can protect themselves by acting early and securing trusted repair professionals before minor issues spiral into critical failures. Whether it’s through routine inspections or urgent interventions, timely electrical repairs are essential to minimizing downtime and maximizing operational continuity.